Production of channel letters

Production of channel letters is one of the core services of JAA Disain – we offer full services – from designing to installation.

We also manufacture the casings of channel letters as a subcontracted service for a large number of advertising companies. When you order the manufacturing of the casing from us, you will not have to handle the most time-consuming and precision-demanding part of the work process. It is usual for advertising companies to use the casings made by us as a basis for their final product.

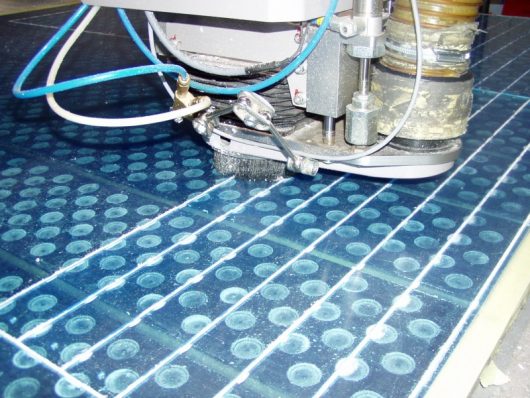

A design of a channel letter is sent to the milling room, where the base and the front of the letter are cut out using a CNC milling machine. This will guarantee a final product that corresponds precisely to the initial file. The next step is sending the same file to the letter-edge machine.

Manufacturing of letter casings and channel letters on the letter-edge machine

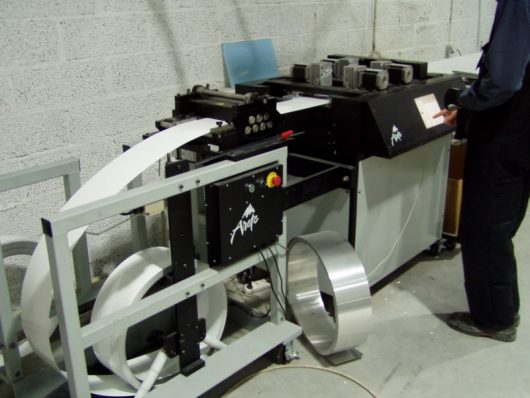

The Arete Return Shop workstation for producing letter-edges is a unique piece of equipment, not found anywhere else in Estonia or several other neighbouring countries. The machine uses the file it has received from the milling machine to measure and cut out the edges of letters. The workstation runs a Windows system and is controlled via a touch-screen.

We use roll aluminium for raw material. The rolls used vary in width, thickness and finishing level of the material. Appropriate materials are selected for each product. From here, the sides of the channel letters move on to another part of the workstation, where their edges are reinforced and/or hemmed under a folding machine. In the next step, the forming of each individual letter starts with a pneumatic folding machine.

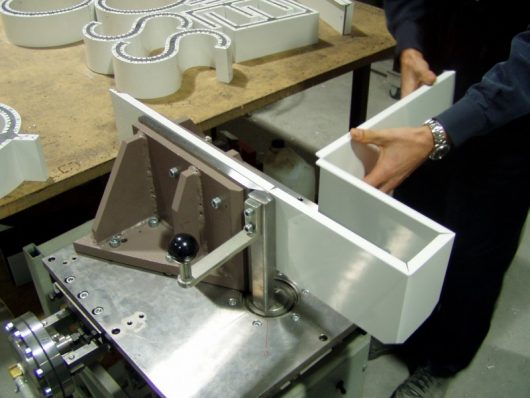

The pneumatic folding machine gives a specific shape to the sides of each letter. The folding machine can be easily adjusted to work on channel letters of various sizes. Next, the sides have to be attached to the end plates.

A clincher is the most reliable, and fastest, machine available for joining sides and end plates. This machine lets us avoid time-consuming operations like riveting, welding, etc. The clincher guarantees very accurate, reliable and fast results.

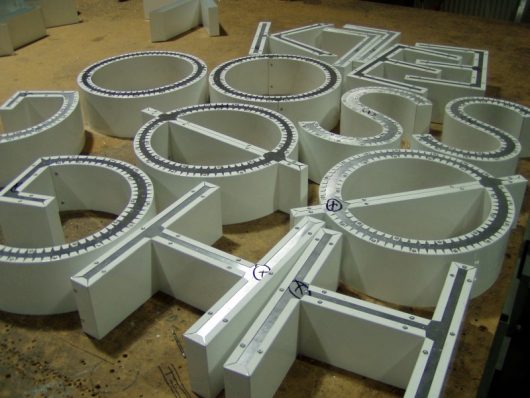

After the sides are attached to the end plates, the letters are ready to be powder-painted, and installation rails can then be attached as well as lighting sources.

See examples of channel letters HERE.